CFD-Simulation

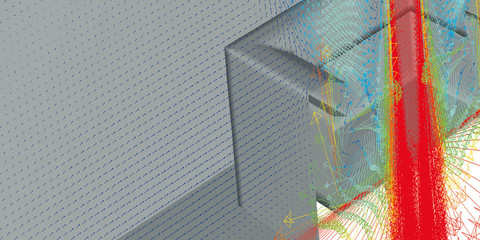

Calculation of flow fields:

The numeric CFD simulation is based on the RANS (Reynolds Averaged Navier Stokes) equations.

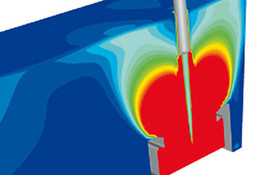

The CFD simulation showed that the piston flow rate was significantly increased by application of a PowerDrum and an even and calm flow field was obtained. The speed the particles travel out of the PowerDrum was reduced to one third. The speed in the remaining flow field of the tundish was considerably reduced also.

The PowerDrum dissipates (eliminates) more energy than common runner pots, thus reducing the turbulence rates on the surface. The turbulence rate of Tu < 2% is well below the turbulent flow expected in technical flows. Despite the low turbulence rates on the surface there are clear differences between the PowerDrum and common rebound pot systems. Both the round and the angular PowerDrum produce lower turbulence rates on the surface of the tundish than comparable rebound pot systems. This applies to the whole surface of the tundish and becomes even more obvious when looking at the mean turbulence rate in the first third of the tundish surface.

Practice

The positive scientific results obtained using the PowerDrums have also proven in practice. WEERULIN PowerDrums have been successful in tests conducted by well-known steel producers and are now a standard product in many plants. The unique combination of splash protection and flow control has convinced both research scientists and practical engineers.

The WEERULIN PowerDrum is always tailor-made to suit the individual geometry of the customer's tundish. For tundishes with bay (t-tundish), we usually suggest a trapezoid runner systems. In the case of narrow rectangular tundishes a round PowerDrum often is the best choice.