Furniture

Power Drum®

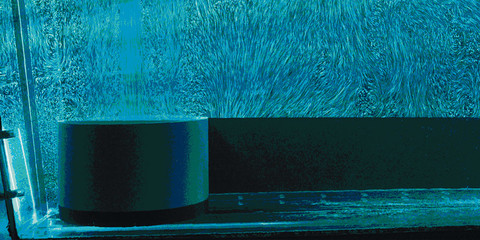

Flow control in the tunish is a key to 'clean steel'. The principal aim during the running phase is to reduce splashing to minimize the take-up of O2. During the following casting steps the aim is to keep the bath surface as quiet as possible while maintaining even flow conditions. The Power Drum developed and patented by WEERULIN combines these functions in an optimum manner. The Power Drum works on the basis of a surprisingly straight-forward principle:

- The metal cover is broken by the blast of steel, but prohibits the penetration of the diverted blast. A sump develops, which reduces the impact energy.

- The cover melts open and the steel flows quietly and evenly over the edges of the device into the tundish.

- The specially designed rebound edge counters extremes of energy and influences the flow conditions throughout the whole sequence period to an optimum.

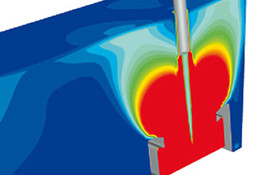

Dams / Weirs

WEERULIN also develops and manufactures conventional manifold systems. Dams, weirs, starter pipes are all part of our product range. Working with you we can develop the ideal manifold system.

| Sector | Type | WEERULING Product | Characteristics |

|---|---|---|---|

| Runner gate | runner drum | Power Drum® | splash reducing, flow controlling |

| Area | integral cast chamber | Splash Box | splash reducing, sump forming chamber |

| furniture | Dämme, Wehre | flow controlling |